The Sim Corder Mill is a remarkable example of engineering innovation that has withstood the test of time. Its story reflects advances in machinery and design and the spirit of human creativity and persistence. This mill has played a crucial role in the development of industrial engineering, combining traditional craftsmanship with pioneering technology.

The Birth of a Vision

The story of the Sim Corder Mill begins in an era when the demand for efficient, reliable manufacturing processes was rapidly increasing. Mills were central to communities and economies, powering the production of textiles, paper, and other essential goods. The founders behind the Sim Corder Mill saw an opportunity to create a facility that would meet this demand and push the boundaries of what was possible with industrial machinery.

This vision led to the creation of a mill engineered for durability and precision. The designers focused on creating machines that could run longer with minimal maintenance. This was a significant step forward because it allowed mills to operate more efficiently, reducing downtime and increasing output.

Engineering Excellence in Design

One of the key features of the Sim Corder Mill is its use of robust mechanical systems that remain effective even decades after their installation. The engineers paid careful attention to the materials used in construction. High-quality metals and reinforced components helped the mill withstand the stresses of continuous operation.

The layout of the mill also reflected thoughtful planning. Machines were arranged to optimize workflow, reducing unnecessary movement of materials. This improved the overall efficiency of the production process. Furthermore, the mill’s design included innovative safety features that protected workers while maintaining productivity.

What sets this mill apart is its blend of mechanical simplicity and complexity. Simple mechanisms worked in harmony with more advanced technology to create a balanced system, allowing operators to manage the mill with greater ease and reliability.

Innovation in Machinery and Mechanisms

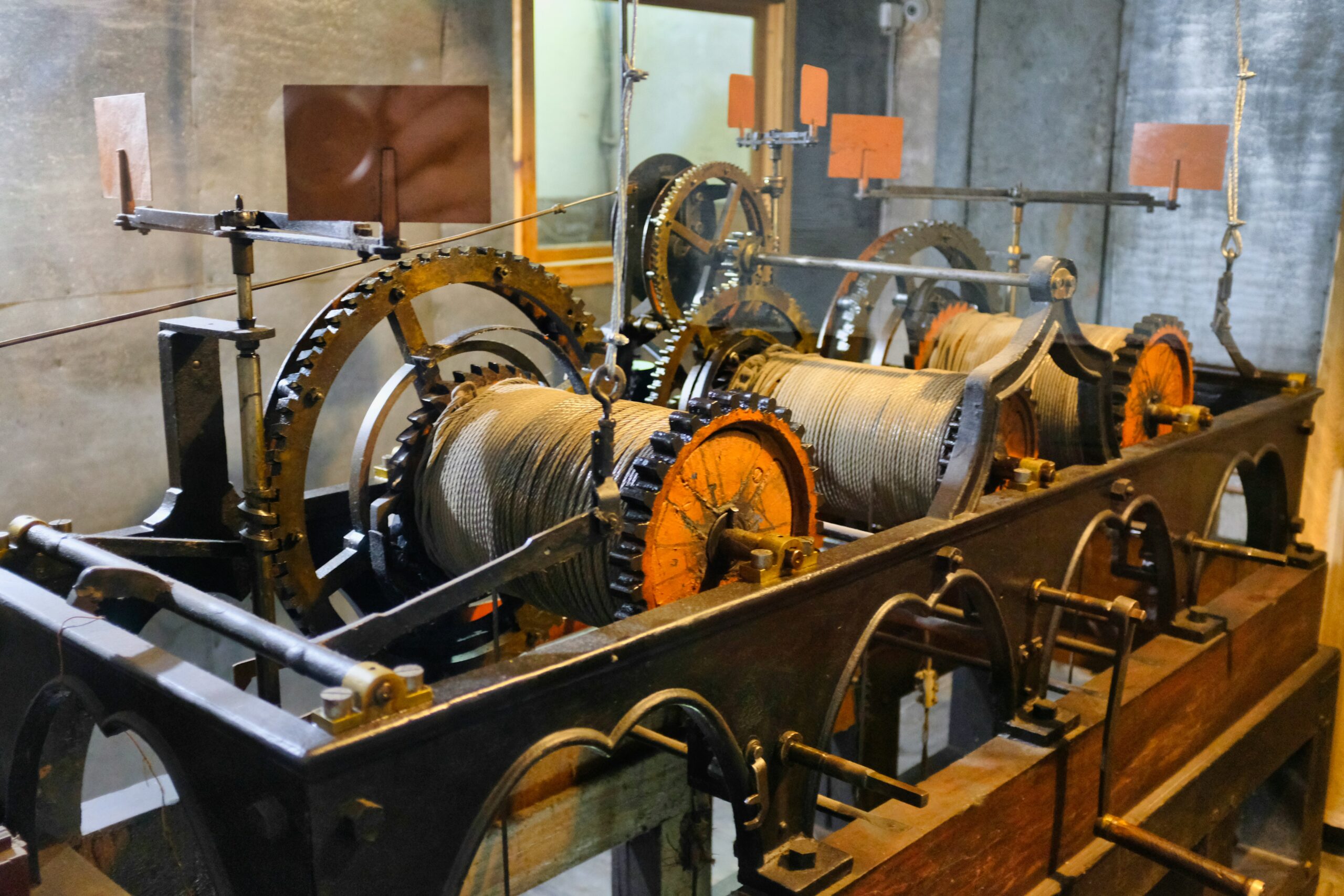

At the heart of the Sim Corder Mill lies its machinery, which was revolutionary for its time. The engineers developed custom equipment tailored to the production line’s specific needs. This bespoke approach meant every machine had a purpose and worked precisely as intended.

One notable innovation was the introduction of improved power transmission systems. Instead of relying on older, less efficient methods, the mill used carefully engineered gear systems that delivered power smoothly and consistently. This reduced wear and tear on components and allowed the mill to run at higher speeds without sacrificing quality.

Additionally, the mill incorporated advanced control mechanisms. These allowed operators to adjust machine settings easily, ensuring the production process remained flexible and responsive to changing demands. This adaptability was rare in early industrial facilities and contributed significantly to the mill’s success.

The Impact on Industry and Community

The engineering achievements of the Sim Corder Mill had a ripple effect far beyond the factory walls. Setting new mill design and machinery standards inspired other manufacturers to adopt similar innovations. This helped accelerate the region’s industrial growth and improved local businesses’ competitiveness.

For the community, the mill was more than just a workplace. It provided steady employment and contributed to the local economy. Families depended on the jobs it created, and the mill became a symbol of pride for the area. Its success showed how engineering innovation could drive both economic and social progress.

The mill also shaped the skills and knowledge of the workforce. Operators and technicians learned to manage and maintain advanced machinery, gaining valuable expertise. This helped build a skilled labor force that supported further industrial development.

Preservation and Legacy

Today, the Sim Corder Mill is recognized as a historic engineering landmark. Efforts to preserve its machinery and infrastructure highlight its importance as an industrial heritage. Visitors can witness firsthand the craftsmanship and ingenuity that went into its design.

Preserving the mill also offers lessons for modern engineers and designers. It shows the value of creating durable, adaptable systems that endure over time. In an age of rapid technological change, the mill reminds us that sustainable engineering practices remain essential.

The Sim Corder Mill’s legacy extends into education as well. It is a case study in engineering courses, illustrating how innovation and practical design come together. Students studying mechanical engineering and industrial management can learn from the mill’s history and the challenges its creators overcame.

Challenges Overcome by Engineering Ingenuity

The construction and operation of the Sim Corder Mill were not without challenges. Engineers had to address issues like power supply consistency, material durability, and process optimization. Their solutions highlight the importance of problem-solving in engineering.

For example, maintaining consistent power delivery was crucial to avoid machine failures. The team implemented redundant systems and regular maintenance schedules. This foresight helped minimize breakdowns and kept production steady.

Material wear was another challenge. The mill’s engineers chose materials that could endure constant friction and load. They also designed parts to be easily replaceable, reducing downtime during repairs.

Process optimization involves balancing speed and quality. The engineers fine-tuned machine settings to achieve maximum efficiency without compromising the integrity of the products. This required careful monitoring and adjustments over time.

The Role of Skilled Workforce

No engineering marvel can operate effectively without skilled people behind it. The Sim Corder Mill relied on experienced operators, mechanics, and engineers who understood the machinery intimately. Their expertise ensured smooth operation and quick responses to issues.

Training was a continuous process. New employees learned from seasoned workers, who passed down practical knowledge. This culture of skill development helped maintain the mill’s high-performance standards.

Moreover, the collaborative environment fostered innovation. Workers and engineers shared ideas to improve machinery and workflows. This ongoing interaction kept the mill at the forefront of industrial technology.

Adaptation to Changing Times

While the Sim Corder Mill was built with early 20th-century technology, it adapted to changes over decades. The management invested in upgrades and retrofits incorporating newer innovations without sacrificing the original design’s strengths.

These updates included improvements in automation and control systems. The mill enhanced precision and efficiency by integrating modern sensors and control units. However, the core mechanical systems remained intact, showcasing the lasting quality of the original engineering.

This ability to evolve while preserving foundational elements is a key reason the Sim Corder Mill remains relevant. It demonstrates how thoughtful engineering allows facilities to keep pace with technological advancements without complete overhauls.

The Sim Corder Mill represents a timeless achievement in engineering. Its design and machinery blend innovation, durability, and practical problem-solving. The mill’s impact on industry and community highlights the power of engineering to drive progress and create lasting value.

Preserving the mill’s legacy offers inspiration for future engineers and a reminder of the importance of building systems that endure. The Sim Corder Mill stands not only as a monument to past achievements but also as a guiding example for innovation in engineering today.