The Sim Corder/Harrison Mill is not just a landmark in mechanical history; it embodies human ingenuity and industrial progress. From its early days as a small operational mill to its present-day status as a symbol of innovation, the mill has continuously adapted to the changing demands of technology while maintaining a respect for traditional craftsmanship. Its engineering brilliance has been the cornerstone of its longevity, ensuring its continued relevance in the modern world.

A Glimpse Into the Mill’s Storied Past

The Sim Corder/Harrison Mill was first constructed in the late 1800s, when America was undergoing significant industrial growth. It began as a simple grain mill, designed to exploit the booming agricultural economy. Built with sturdy materials and powered by steam engines, the mill initially relied on human labor for its day-to-day operations. However, its success came not just from its strategic location, but also from its efficient design. It was soon apparent that the mill had the potential to grow beyond its initial scope.

As the decades passed, the mill underwent upgrades, reflecting the ever-evolving technological landscape. One of the significant turning points came in the early 20th century when the mill adopted more mechanized processes. This allowed it to produce grain more efficiently and at higher volumes, helping it to meet the demands of an expanding economy. By the mid-1900s, introducing electric-powered machinery allowed the mill to boost production further, cementing its role as a key player in the regional industrial scene.

Innovative Engineering Design

What sets the Sim Corder/Harrison Mill apart from others of its time is the innovative design that incorporates both traditional and modern engineering techniques. The mill’s structure consists of steel and iron elements that provide exceptional strength and durability. Its intricate system of gears and pulleys, which work in perfect unison, is a testament to the precision engineering involved in its construction.

The mill is also a marvel of water-powered technology. The nearby river plays a crucial role in the mill’s energy system, as it powers turbines that generate the necessary energy to run its various machines. This sustainable energy source was a breakthrough in its time and remains a key feature of the mill today. Using water power and electricity ensures that the mill remains environmentally responsible while maintaining high productivity levels.

The Role of Automation in the Mill’s Operations

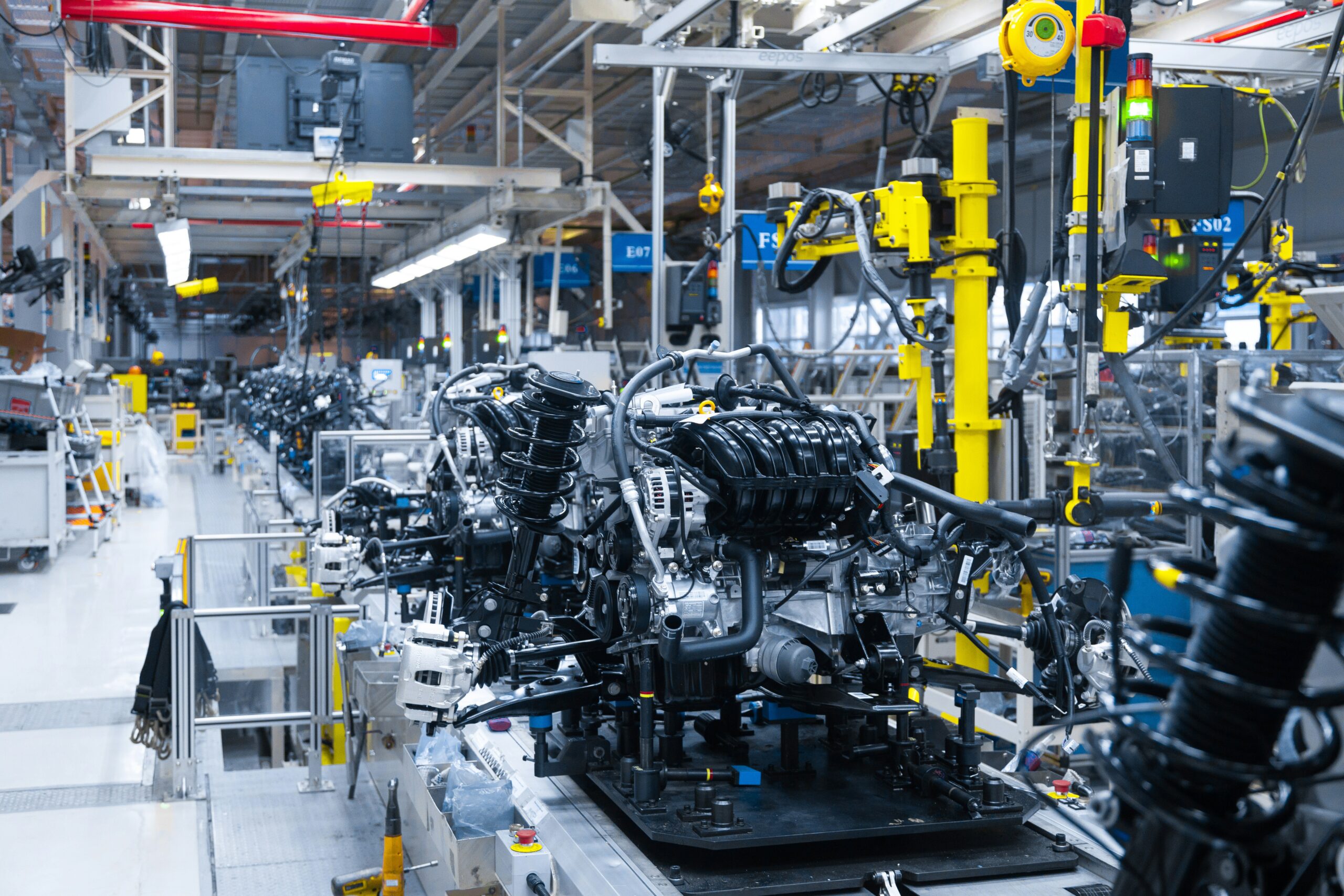

The mill has embraced automation in recent decades, significantly boosting its efficiency and precision. By incorporating modern computerized control systems, the mill can operate more accurately, minimizing human error and maximizing output. Sensors and monitoring equipment track the progress of every stage in the manufacturing process, ensuring that the products meet the highest quality standards.

Integrating advanced technology into the mill’s operations has allowed it to stay competitive in a rapidly changing industrial landscape. With automation, the mill can produce at a pace and scale that would have been unimaginable during its earlier days. It also enables the mill to operate with fewer workers, cutting labor costs while improving safety and consistency in production.

Preserving Heritage Through Modern Technology

While the mill has undergone significant technological upgrades, its commitment to preserving its heritage remains unchanged. The current team of engineers and operators at the Sim Corder/Harrison Mill takes great pride in maintaining the mill’s traditional processes. For example, the intricate mechanical systems that once powered the mill by hand are now meticulously restored and preserved as a part of the mill’s legacy.

This combination of old and new is what makes the mill unique. The use of modern technologies like computer systems and automation does not erase the mill’s historical elements. Instead, it enhances them, blending the rich history of mechanical craftsmanship with the convenience and efficiency of contemporary engineering. The result is a mill that operates efficiently and serves as a living history lesson for future generations of engineers and industrial enthusiasts.

The Economic and Community Impact

The Sim Corder/Harrison Mill has been more than just a center of industry; it has been a central part of the local economy and community. Over the years, it has provided numerous jobs to people in the area, contributing to the financial well-being of the region. The mill’s ability to sustain itself while offering stable employment opportunities has made it a pillar of the local workforce.

Additionally, the mill has helped boost local businesses by providing raw materials for various industries. It has acted as a catalyst for regional development, attracting other businesses and stimulating economic growth. As the mill continues to thrive, it remains an integral part of the community, offering employment and educational opportunities for those interested in learning about industrial technologies.

Paving the Way for Future Innovation

Looking toward the future, Sim Corder/Harrison Mill is embracing cutting-edge technologies to optimize its operations further. Artificial intelligence (AI) and robotics are expected to play a key role in its next development phase. These advancements promise to increase productivity and reduce operational costs while maintaining the high standards that have defined the mill for over a century.

The mill also focuses on environmental sustainability. They are implementing new technologies to reduce waste and conserve water, ensuring that the mill’s operations have a minimal impact on the surrounding ecosystem. These forward-thinking initiatives demonstrate that the Sim Corder/Harrison Mill is concerned with its immediate success and the well-being of the world it inhabits.

A Lasting Legacy of Innovation

The Sim Corder/Harrison Mill is a shining example of what can be achieved when engineering brilliance, traditional craftsmanship, and forward-thinking technologies come together. Its long history is marked by constant innovation, ensuring that the mill continues to meet the demands of the modern world without sacrificing its rich heritage. As the mill evolves to incorporate new technologies and methods, it remains an integral part of both industrial history and the future of manufacturing.

Its story inspires engineers and industry professionals everywhere, showing that the pursuit of excellence and sustainability can coexist. The Sim Corder/Harrison Mill is more than just a working industrial site—it’s a beacon of progress, a living tribute to the power of innovation. Each passing year solidifies its place in the annals of engineering history, proving that even in a fast-paced, ever-changing world, some legacies are built to last.