The history of American industrialization is deeply intertwined with the rise of mills across the country. These mills were the driving force behind the shift from agrarian economies to industrialized ones, providing essential products and services while helping to shape local economies. Among these mills, the Sim Corder/Harrison Mill stands as a prime example of how industrial operations contributed to the early economic and social changes that defined America’s growth. The story of the Sim Corder/Harrison Mill provides insight into how a single industrial operation can influence its surrounding community and help pioneer industrial techniques that would eventually spread across the country.

The Early Role of Mills in Industrial America

Before the widespread use of factories and large-scale mechanization, mills served as the foundation of early industry in the United States. The primary function of these mills was to process raw materials like grain, timber, and wool, converting them into more valuable products for communities. Water-powered gristmills, sawmills, and later textile mills were at the heart of early industrialization, supplying local economies with food, building materials, and textiles, among other vital goods.

These mills became the cornerstone of rural economies, serving as central hubs where goods were produced, labor was concentrated, and innovation could thrive. They marked the beginning of a new economic model that relied on specialized manufacturing and the use of renewable energy sources, such as water power.

The Sim Corder/Harrison Mill was one such critical establishment that mirrored these early trends in American industrialization. Over time, it evolved from a small-scale gristmill into a significant player in its region, highlighting the broader transformation occurring in the United States during the 19th century.

From Gristmill to Industrial Hub: The Evolution of Sim Corder/Harrison Mill

The Sim Corder/Harrison Mill, founded in the early 1800s, began its life as a modest gristmill serving the local agricultural community. Located near a flowing river, the mill harnessed the power of the water to grind grain, a necessity for feeding the growing population of the surrounding area. Early American mills were vital to the success of farmers, who relied on these structures for transforming their crops into marketable goods.

By the mid-1800s, as industrialization began to take off in the United States, the Sim Corder/Harrison Mill transitioned into a more complex industrial operation. Ownership passed from one family to another, and with each change, the mill expanded its operations and its technological capabilities. New machines were introduced, increasing the mill’s ability to process different raw materials and serve a broader market. The once small gristmill now included a sawmill, producing lumber and timber for construction, as well as other machinery that facilitated the production of textiles, tools, and other products.

This transformation from a basic agricultural tool into a multi-purpose industrial hub mirrored the broader economic shifts happening across the nation, where small, localized operations were growing into larger, more integrated systems capable of meeting the demands of an expanding market.

Technological Innovations: Steam Power and Machinery

One of the most significant factors in the success of the Sim Corder/Harrison Mill was its ability to adapt to the technological changes that characterized the industrial era. Initially powered by water wheels, the mill’s owners began incorporating steam power in the mid-1800s. Steam engines, which had become increasingly popular during the Industrial Revolution, offered a more reliable and consistent power source, enabling the mill to operate year-round regardless of fluctuating water levels in the river.

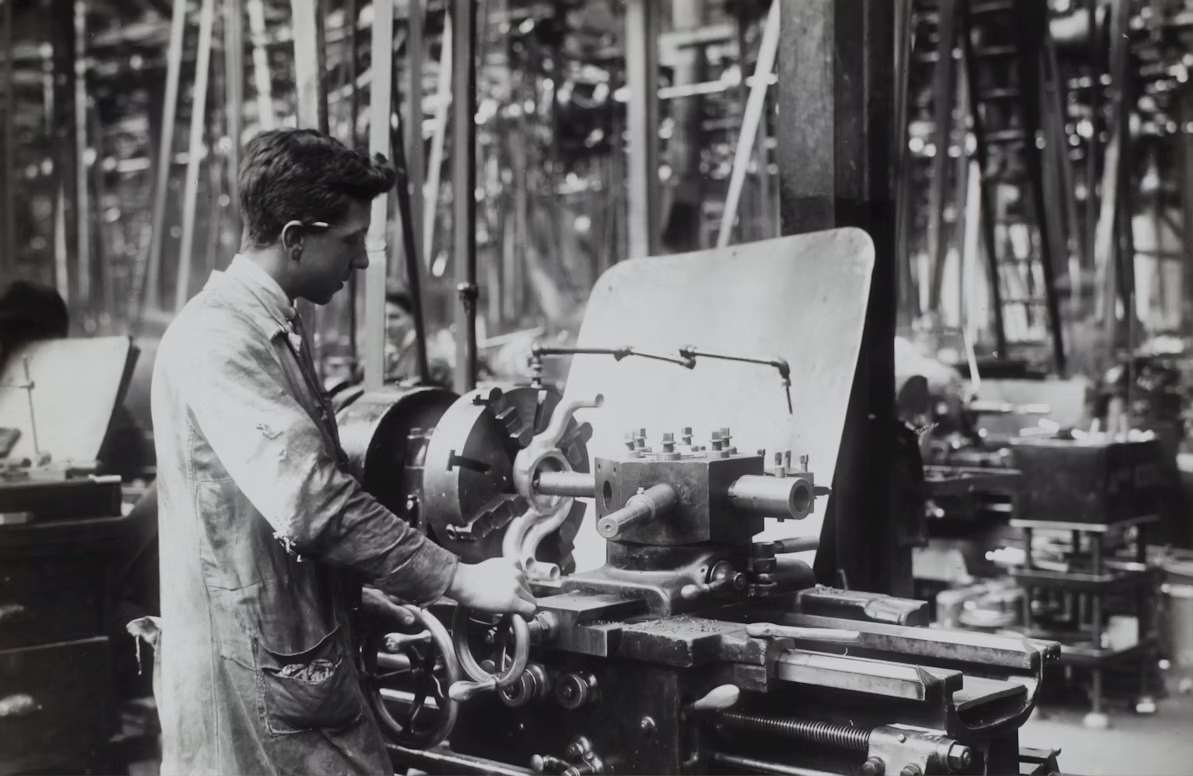

This switch to steam power was crucial for the mill’s continued viability, as it allowed the operation to expand its capacity and produce goods on a larger scale. Along with steam power, the mill incorporated advanced machinery that could perform tasks faster and more efficiently than ever before. This included automated systems for processing raw materials and more complex designs for producing flour, lumber, and textiles.

The technological innovations at the Sim Corder/Harrison Mill were a microcosm of the larger trends seen throughout the United States during the Industrial Revolution. The advent of steam-powered machinery revolutionized production methods, giving rise to the rise of large factories, urbanization, and changes in labor practices that would have lasting effects on American society.

Economic Impact and the Rise of the Mill Town

As the Sim Corder/Harrison Mill grew, it played an integral role in shaping the local economy. By providing jobs for hundreds of workers, the mill became the heart of the community. It was common for mills to act as both employers and economic hubs, fostering the growth of surrounding businesses, from blacksmiths to carpenters to stores that sold goods produced by the mill.

The growth of the mill also led to the development of infrastructure in the surrounding area. Roads were built to facilitate the movement of raw materials and finished products, and homes and shops were constructed to house mill workers and support their families. In many cases, a mill town would emerge around such industrial hubs, transforming rural communities into burgeoning centers of industry and commerce.

However, like many early industrial operations, the rise of the Sim Corder/Harrison Mill also had its darker side. The harsh working conditions in mills and factories, especially for women and children, became a pressing concern as industrialization advanced. Workers often faced long hours, low wages, and dangerous environments, which led to early labor movements and calls for reform.

Despite these challenges, the mill remained a critical component of the local economy and played a key role in the economic success of the area. Over time, the influence of mills like Sim Corder/Harrison would ripple outward, supporting not only regional industries but also contributing to the broader growth of the American industrial economy.

The Decline and Legacy of the Mill

As industrial techniques continued to evolve, the role of mills like Sim Corder/Harrison began to decline. New factories and more advanced technologies emerged, offering greater efficiency and scale than older mills could achieve. The rise of the railroad also changed transportation patterns, making the centralized location of water-powered mills less critical.

Though the Sim Corder/Harrison Mill eventually closed, its legacy lives on. Today, it serves as a historical symbol of early American industrialization, representing both the opportunities and challenges of this transformative period. The mill’s role in shaping local economies, advancing technological innovation, and supporting industrial growth makes it an essential part of America’s industrial history.

The Sim Corder/Harrison Mill is more than just a historical landmark; it is a microcosm of the early American industrial experience. From its humble beginnings as a gristmill to its expansion into a multi-faceted industrial operation, the mill embodies the larger economic, technological, and social changes that defined the early industrial era. While the mill itself may no longer be operational, its contributions to local economies, labor systems, and industrial development continue to be felt today. As we reflect on the legacy of mills like the Sim Corder/Harrison Mill, we gain a greater understanding of how small-scale industrial operations paved the way for the larger factories and manufacturing systems that transformed the United States into an industrial powerhouse.